Fixed Film (Sand or Other Media) Filters

Media filters are aerobic, fixed-film wastewater treatment systems. Sand is the most commonly used medium for treating both water and wastewater. Single pass sand filters have been used for well over 100 years and historical uses of this system date back to late 1890’s. Use of other media such as gravel, peat fiber, crushed glass, textile, foam, etc., is gaining popularity in onsite industry as we gain knowledge on how the performance of media filter systems can be improved for onsite wastewater treatment.

Wastewater treatment mechanisms that occur in a sand filter include physical, chemical, and biological processes. Physical processes such as straining and sedimentation remove suspended solids (measured as TSS) within the pores of the media. Chemical adsorption of certain pollutants such as phosphorus or heavy metals plays a limited role and it depends on the characteristics of the medium used in the filter. On the surface of the media, biofilm is developed from the growth of the microorganisms as wastewater moves through the media. The microorganisms active in the biofilm absorb soluble and colloidal waste materials (measured as BOD5 or COD) as the wastewater percolates over the sand surfaces. As a result of the biochemical and physical treatment processes, pollutants such as BOD5 and TSS are significantly reduced and most of the ammonia nitrogen is converted into nitrate nitrogen (nitrification). Dissolved oxygen level in wastewater is increased and the treated effluent looks clear and does not smell like septic tank effluent.

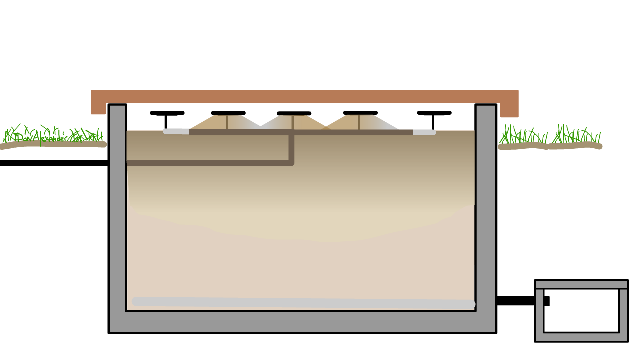

A media filter treatment unit has the following basic components:

- A container, typically a concrete tank;

- An under drain system for removing treated effluent, typically a slotted PVC pipe;

- Treatment medium, typically sand;

- A dosing and distribution system to apply wastewater on top of the media, typically a PVC pipe with orifices or spray nozzle; and

- Dosing tank containing pump and control system.

Desired treatment goals for a given type of wastewater can be achieved by carefully selecting media for treatment and appropriately designing the treatment system.

Major design parameters for a single pass media filter are:

- Loading rate (hydraulic and organic)

- Effluent distribution system, and

- Characteristics of the media.

Major design parameters for a recalculating (also called multi-pass) media filter system are:

- Loading rate – hydraulic and organic,

- Recirculation ratio,

- Effluent distribution system,

- Liquid volume of the recirculation tank, and

- Characteristics of the media

In a single pass media filter system, primary effluent (septic tank effluent) is applied (dosed) on top of the filter at certain time interval. As shown in the animation, when the distribution network (pipe) is filled with wastewater, spray nozzles apply the wastewater uniformly on top of the media (sand). Note that the effluent can also be applied on top of the filter using a network of perforated pipes that is placed on top or a few inches within the media. Spraying effluent on top of the media offers advantage in terms of allowing air to mix with the effluent. However, spraying of primary effluent will increase the potential for odor and adequate odor control system must be incorporated in the design. Use of spray nozzles in an adequately designed and operated recalculating media filter pose very little or no potential for odor since the effluent that is sprayed is the mixture of primary effluent and the treated effluent.

Amount of effluent applied on top of the media in every dose must be such that at the end of the dosing cycle, the effluent should not have reached the bottom of the filter, thus avoiding flooding of the media. As shown in the animation, as the spray nozzles stop spraying effluent, the wetting front has reached about half way in the filter and it continues to move downwards towards the under drain system. It is important that the media filter is adequately ventilated and airflow through the media is achieved. In some media filter, forced ventilation using a fan or a blower is incorporated into the design to ensure that adequate supply of air is available to achieve aerobic treatment.

Once the dosing of effluent is stopped on top of the media, a few minutes later, the filter starts draining. Effluent is collected at the bottom of the media using the under drain and is removed from the media filter.

In a single pass system, treatment is completed after one pass and is ready for dispersal into a subsurface effluent dispersal system. However in a recalculating system the effluent is collected in a recirculation tank and is dosed back to the media filter

The main difference between a single pass media filter and a recalculating media filter is the size of the system. Typically, a single pass system is larger in size than a recalculating system. However, a recalculating system is typically more complex in terms of pumps and control system. Recirculation of the effluent in a recalculating media filter is achieved using a split flow method (distribution box) in which part of the drain back flow is returned to the recirculation tank and the rest is discharged. In a split flow method, total number of times the filter is dosed in a day will depend on the amount of wastewater generated on that day. Recirculation of the effluent can also be achieved using a ball float valve that is installed in the recirculation tank. Depending on the water level in the recirculation tank, the ball float valve will either allow the drain back flow to return back into the recirculation tank or divert it to the discharge tank. This method allows fixed number of doses onto the filter every day regardless of the amount of wastewater generated. Performance of a recalculating media filter that is dosed fixed number of times everyday is typically better than the one that is not dosed fixed number of times.

At Virginia Tech Kentland Research Farm, Prof. Ray Reneau has evaluated performance of a pre-engineered pre-packaged recalculating media filter system over a period of three years. More information on this project can be found at http://filebox.vt.edu/cals/cses/reneau/projects/rmfsum.html. Recalculating media filter evaluation at the Virginia Tech was done under highly “controlled” condition in which exact amount of septic tank effluent (designed flow) was added to the treatment process every day during the evaluation process and samples of treated effluent were collected for analysis.

Division of Onsite Sewage and Water Services was involved in a field evaluation of a single pass peat filter system from 1996 through 2000. During this period, hundreds of peat filters were installed to serve single homes in Virginia and 24 sites were selected for evaluation of the filter performance and for determining impact on shallow groundwater quality from discharge of the filter effluent. A technical paper was presented during the ASAE conference in 2000 presenting the results of this study (link to the file).

In May of 2000, four different types of recalculating media filters were installed in a subdivision to repair failing septic tank effluent drain field. The media used in each of these filters is different and so is the size of the filter and the recalculating method. However, effluent quality appears to be quite similar and of high quality that was good enough to rejuvenate the drainfields that were failing prematurely. Details on Genito West project are contained in the file (Gentio West Project.doc).

All types of media filter system will need maintenance and a professional with adequate training in operation and maintenance of this type of system must be present in the area where use of media filter is proposed.